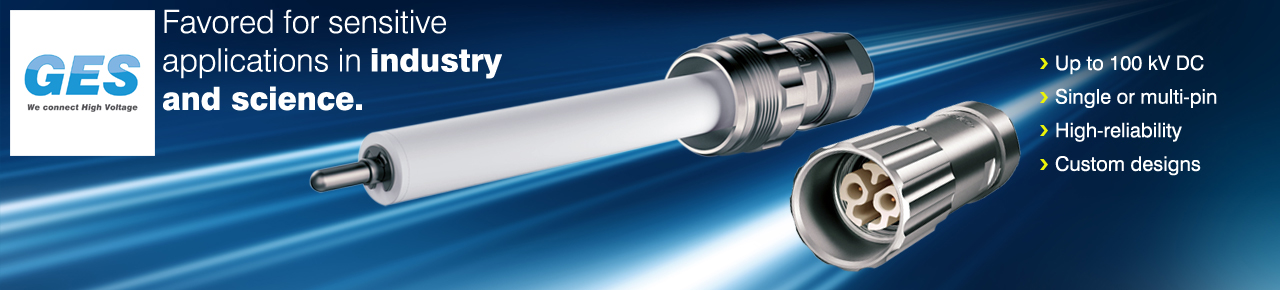

(GES what's new, NLQ4/15) Investing in a 3D printing system has significantly accelerated our capabilities in the field of application- and customer-specific product development and provides significant advantages to the customer. After all, Agilista-3000 has some interesting refinements ...

The decision for Agilista-3000 is partly due to the fact that miniaturization is a trend with high voltage connectors too and the electromechanical gets increasingly complex. In addition, the system should also be able to not only produce haptic and graphic samples but functional components that can be tested under electrical conditions.

With its high-resolution precision of 15 microns in coating thickness and water-soluble (!) support material Agilista-3000 met the requirements. While the more common manual removal of the support material can easily cause damage or adhesions, water-soluble support material allows residue-free cleaning even with the smallest diameters and without additional peripheral devices such as ultrasonic cleaners or tempered tanks. And since the model material used is transparent, visual inspection of the internal structure is also possible. Ultimately, the easy maintenance and integration into the IT environment was convincing.

For GES Agilista-3000 is a perfect solution and a successful launch into the exciting future of 3D printing.